Living with Silicone

- HOME

- Living with Silicone

Nobuhisa Kawaguchi, founder of Fuji Systems, focused on the characteristics of silicone and opened up new possibilities in the medical field. Silicone is chemically stable with high biocompatibility and flexibility, and plays a very important role in the development of medical devices. Fuji Systems continues to work with silicone to contribute to the life and health of people.

To Realize Minimally Invasive Surgery

Our idea of applying silicone to medical devices was motivated by its high biocompatibility. More specifically, silicone catheters and devices cause extremely low allergic reactions in bodily tissues even if they are retained in the body. This can help achieve higher safety with minimum strain on the patient's body. However, there was the problem of friction with bodily tissue during insertion, which makes it difficult to insert it smoothly. We successfully reduced the pain and discomfort of patients by making the surface of silicone catheters and devices hydrophilic, which also helped doctors and nurses perform procedures more smoothly. We have been accumulating unique knowledge and technology to take full advantage of the superior characteristics of silicone and obtain desired characteristics that suit the objective.

Breakthrough with Creativity and Technological Capabilities

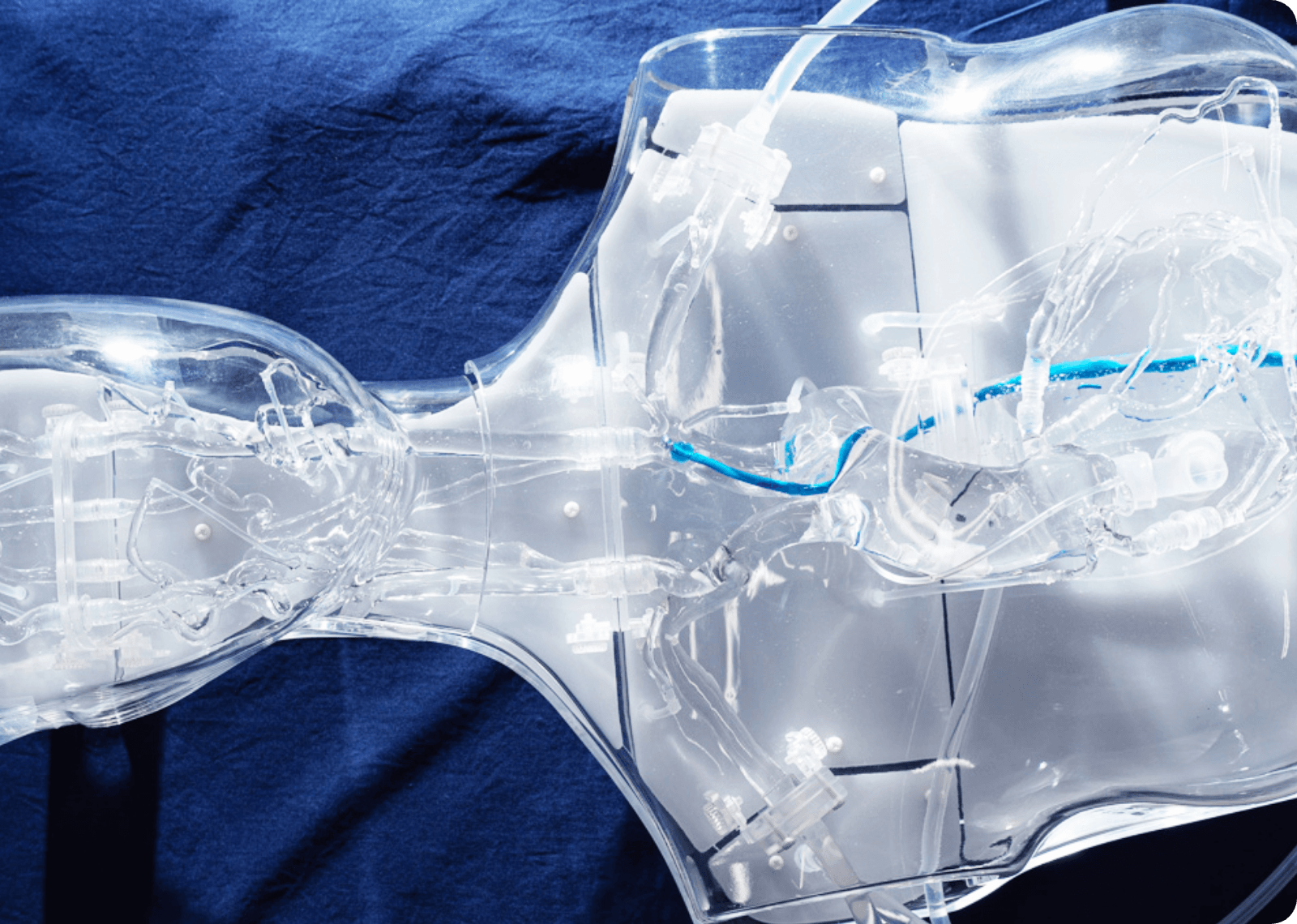

One of our important challenges toward the future is the development of medical devices that can be manipulated by doctors as needed inside the patient's body. For example, silicone devices built into endoscopes and laparoscopes allow for a variety of treatments and procedures. What we provide is the knowledge and technology to use silicone effectively. Silicone has various grades of flexibility and unique characteristics, and is a very important material to help embody the ideas of doctors. Our expertise includes not only silicone itself, but also processing technology to build it into the mechanisms of medical devices. We have developed it over the years with doctors, which gives us creativity and technological capabilities that amaze doctors with achievements they never expected.

Turning the Gas Permeability of Silicone into New Values

Silicone has a unique characteristic called gas permeability. It allows for permeation of various gases, such as oxygen, carbon dioxide, and nitrogen. Its gas permeability is especially high among many kinds of resins. As a result, it is widely used for separation membranes that allow for permeation of specific substances into gases and liquids. Other resins used for separation membranes include polypropylene, polymethylpentene, and polyethylene. These resins have a porous structure with microscopic pores and are used for medical applications such as artificial kidneys and artificial lungs. However, artificial lungs using porous membranes have the challenge of forming blood clots during gas exchange, resulting in clogging. We focus on silicone membranes as one possibility to deal with this challenge. We have been conducting research on artificial gills by focusing on the gas permeability of silicone. We are in the process of trial and error to resolve problems by taking advantage of the experience. We are conducting research and development to help patients with trouble breathing live longer and improve their quality of life.

Taking on the Challenge Together Toward a Healthy Future

Since the foundation, Fuji Systems has been working on research and development with partners and medical professionals who want to develop new products. While we believe in the potential of silicone and continue developing processing technology for it, we work on joint research to meet the expectations of partners and medical professionals who want to develop new products as well as patients. We make it our mission to contribute to the development of medicine and the life and health of people, and will continue to work hard toward the goal.